Technologies

Our company is full cycle EMS provider offering equipment manufacturers all the technologies and operations, such as surface mount, through hole mount, soldering, testing and packaging.

Our services also includes returns and repair.

Our technologies are:

Surface mount (SMT)

SMT assembly includes: applying soldering paste, placing SMT components in the soldering paste areas on PCB and soldering the boards using the reflow process.

Through Hole (THT)

We provide both selective soldering using Pillarhouse machine and line Wave soldering using Seho.

Conformal coating & Potting

We have a conformal coating line consist of PVA machine and IR curing oven. We do polyurethane or other two component compound bubble free potting with thermal curing using a special liquid controlling system with metering, material heating and mixing.

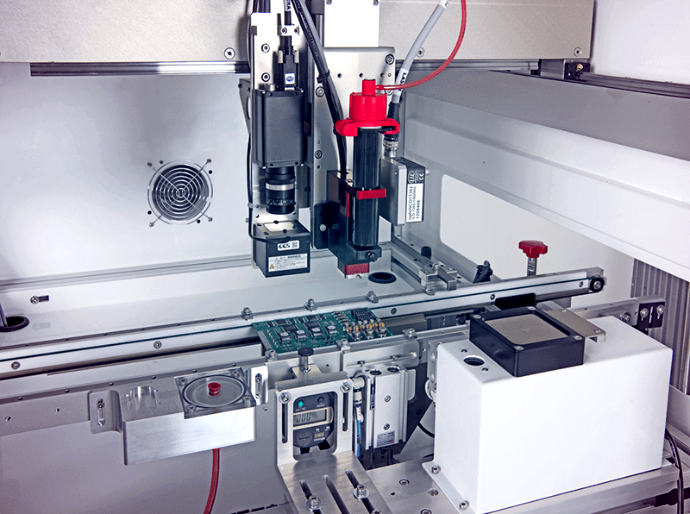

Selective soldering

We have a conformal coating line consist of PVA machine and IR curing oven. We do polyurethane or other two component compound bubble free potting with thermal curing using a special liquid controlling system with metering, material heating and mixing.

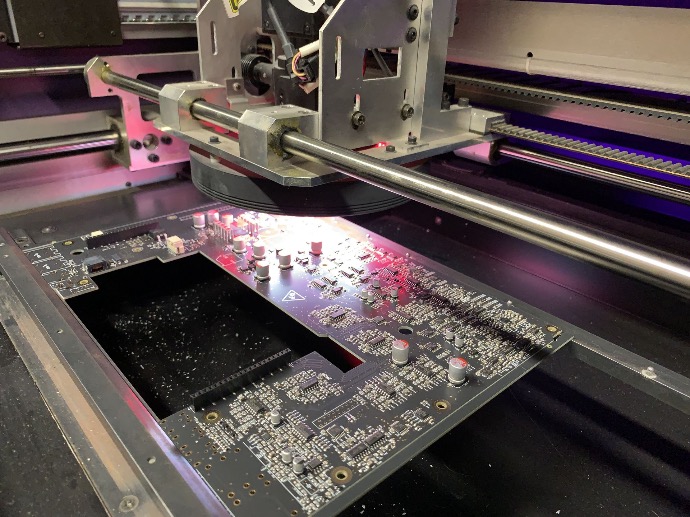

AOI Inspection and Visual Check

During the final step of the SMT production process, an Automated Optical Inspection (AOI) is performed to make sure that all components have been soldered correctly and that the boards are ready for delivery.

The AOI visual check ensures consistency and accuracy in the SMT assembly production process.

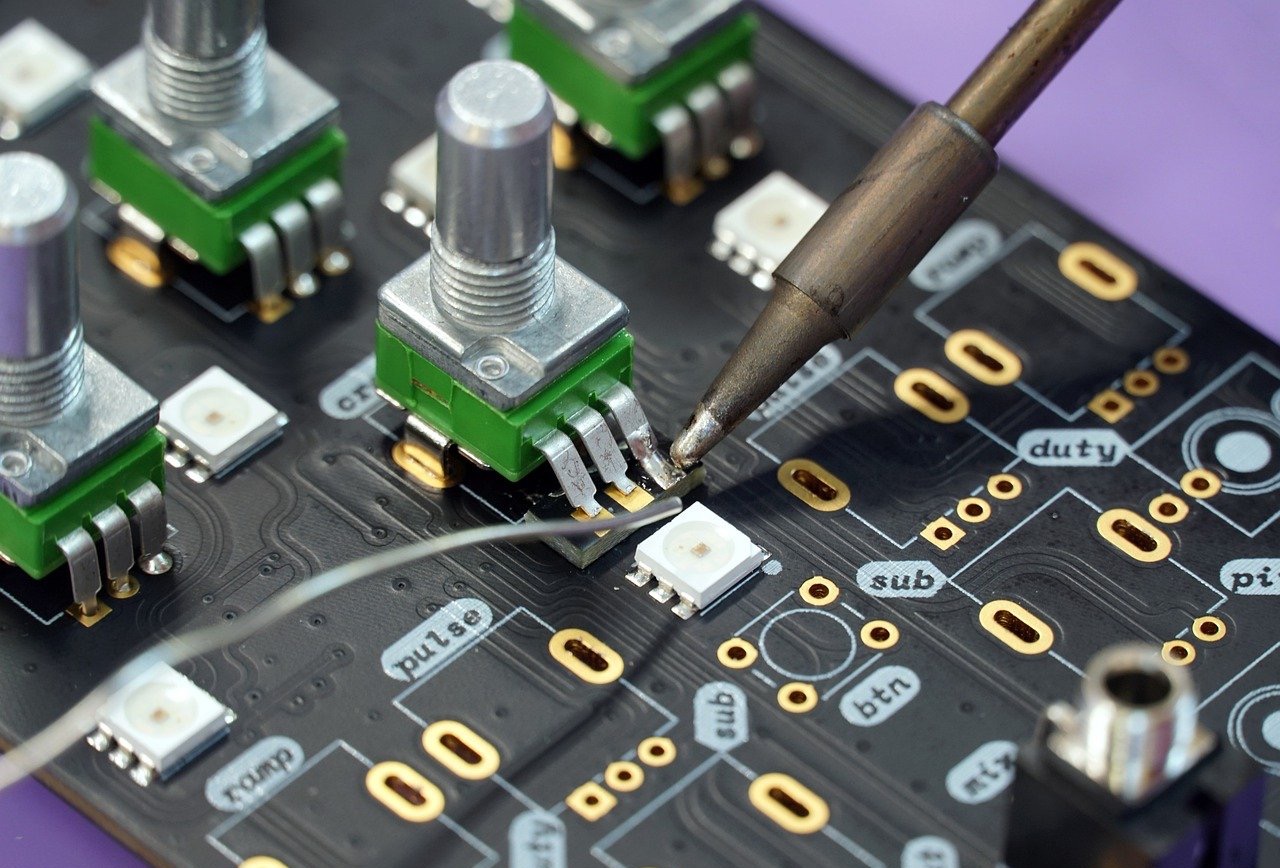

Rework

We use Martin rework station with mixed IR/hot air preheat capable to work with 0201 to BGA packages.